Ideal If...

|

|

|

Cantilever Rack

WHAT IS CANTILEVER RACK

It is specifically designed to store long loads such as beams, profiles, pipes and timber. This rack enables loads to be handled by using lifting systems such as lift trucks, mobile cranes, stacker cranes, etc. These systems are chosen depending on the load to be stored (mainly weight and dimensions) or the height of the rack itself.

The system consists of columns with a vertical beam and one or two horizontal beams at the base to provide stability. A series of arms are attached on which the load is placed. These columns are made of hot-rolled metal beams at variable heights enabling to be fitted. Moreover, its design allows the loads to be fitted on one side of the structure only, or on both sides.

Advantages

- Easy-to-assemble. The parts are designed to allow the shelves to be assembled quickly and easily.

- Structure of great simplicity and strength.

- All the elements involved fit together easily and allow excellent mobility.

HOW IT WORKS

Cantilever racking systems are ideal for storing long goods or other non-standard sized items. The product can be loaded and unloaded quickly. Cantilever rack also prevents damage from bulk stacking. It is an ideal rack system for pipe, tubing, bars, rods, plastic sheet, sheet metal, lumber, and plywood. Commonly used in manufacturing facilities and warehouses.

All cantilever uprights from NUTECH can be used as single-sided or double-sided designs and the rows of uprights can be any length required. The cantilever arms can be modified flexibly for stored goods with different heights and loading requirements. Subsequent adjustments and adaptations can be made.

Based on your type of goods, warehouse space, equipment available, and existing foundation, NUTECH will design and implement the suitable cantilever rack for you.

Nutech Cantilever Rack for storing long goods

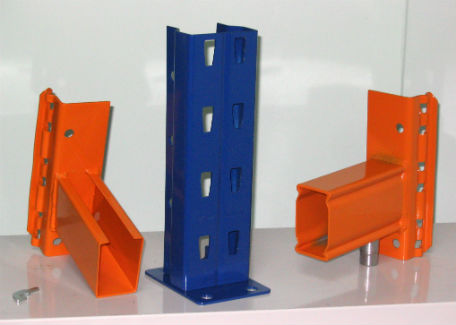

NUTECH Cantilever Rack - Enhanced Base.

Left: Longspan with Fork Spacers. Right: Medium Cantilever Rack for uprights Long Products, Coils, and other odd size goods.

Light Duty Cantilever Rack with metal shelving for loose products.

General Benefits

Easy-to-assemble

The parts are designed to allow the shelves to be assembled quickly and easily.

Great Simplicity and Strength

All the elements involved fit together easily and allow excellent mobility.

Perfect to store long and heavy items.

Store long and heavy item on Cantilever Rack instead of laying them on the floor.

Flexible Operation

Its design allows the loads to be fitted on one side of the structure only, or on both sides.

Components and Options

Frame

- 1.6mm, 1.8mm, 2.0mm thick

- N60, N90, N115

- Epoxy coated or Galvanized frame

The Details

Nutech selective pallet racking is made with the same frames as our well established pallet racking system. It is fully screwed in place and particularly well suited to heavy loads. At the top end, the frames are connected to each other with struts in side-to-side and in front-to-back direction. Additionally, the uprights of each frame are linked to each other by horizontal and diagonal struts to ensure that all parts of the frame are solidly connected to provide excellent rigidity.

.jpg)

Hook-in Beam

- Rapid assembly

- Adjustable height

- For heavy-duty applications

The Details

Rapid assembly thanks to a straightforward boltless system: The 3 or 4 hooks of the bracket perfectly slot into the upright perforations. Unintentional lifting is prevented by a safety pin which is secured against dropping out by a 90' turn. The hooked bracket is also designed to hold heavy loads and its height can be adjusted in 75mm intervals.

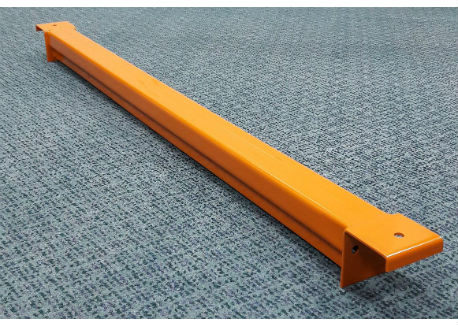

Pallet Support Bar

- Heavy duty, welded cuff design

- Easy installation, drops in place

- Epoxy powder coated

The Details

The pallet support bars provide additional safety and security under your pallet when installed in pallet racking system. Reduce load times because they give forklift driver confidence in loading pal

Frame Protector

- Protects the frame from damage

- Epoxy coated

The Details

The frame protector is placed at the further end of a row to protect the frame from damage or collision with material handling equipment.