Ideal If...

|

|

|

HOW IT WORKS

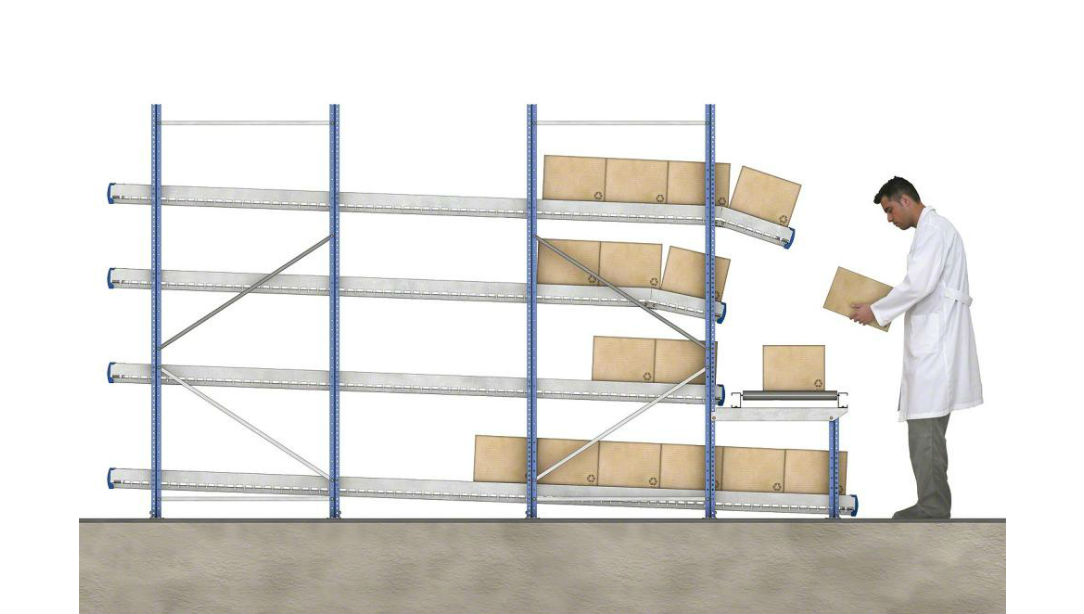

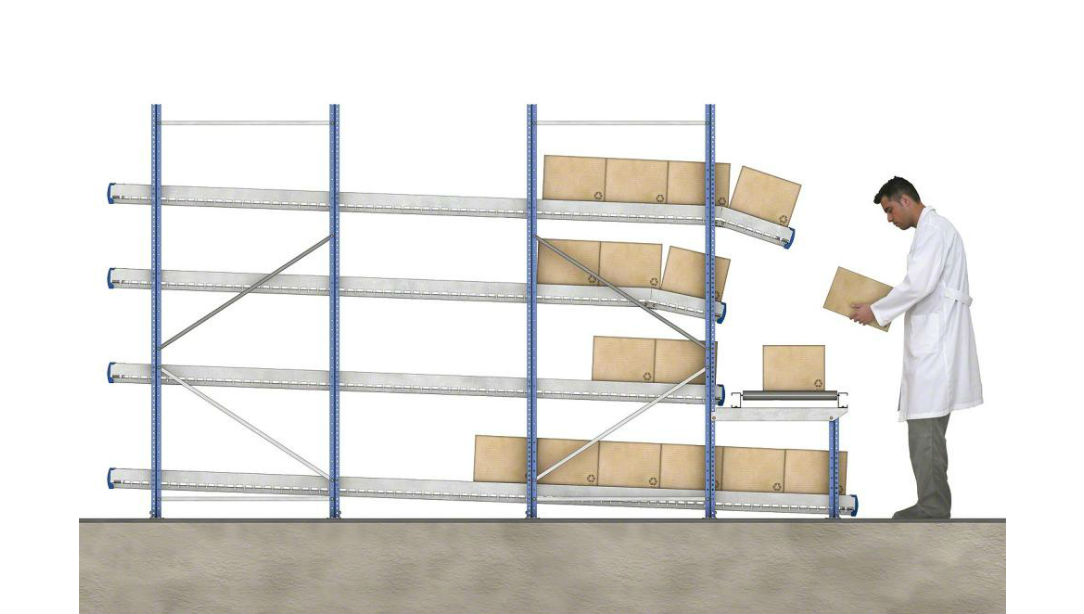

Carton Flow Rack systems for every size warehouse and every price range are gravity-drive and perfect for applications with numerous SKUs. Inventory rotation is ensured with First-In-First-Out basis. Separating the loading aisle from the retrieval aisle allows pickers to operate more efficiently. Carton Flow Rack uses sloped shelves to improve visibility and order accuracy and is the perfect answer for a split case or piece picking.

Carton Flow Rack can be integrated with conveyors and other warehouse storage solutions to create functional pick modules and picking efficiency.

Carton Flow Rack can dramatically improve warehouse efficiency by organizing product and rotating stock automatically. Long, straight, dedicated lanes maintain product organization and keep labor costs down. Storage space can be increased up to 60% by using a minimum of 22% less floor space, thereby keeping building costs down.

Typically, Carton Flow Rack Systems use about half the floor space that standard pallet rack and the difference can be more dramatic with multi-level systems. The simplicity of gravity-driven systems requires less capital than maintenance-prone automated systems.

NUTECH Carton Flow Rack - Placon Rack. Inclined at a small degree to allow cartons to flow naturally and slowly by gravity pull.

NUTECH Carton Flow Rack - Placon Rack. Stopper bar at the output to prevent goods from falling off the shelf.

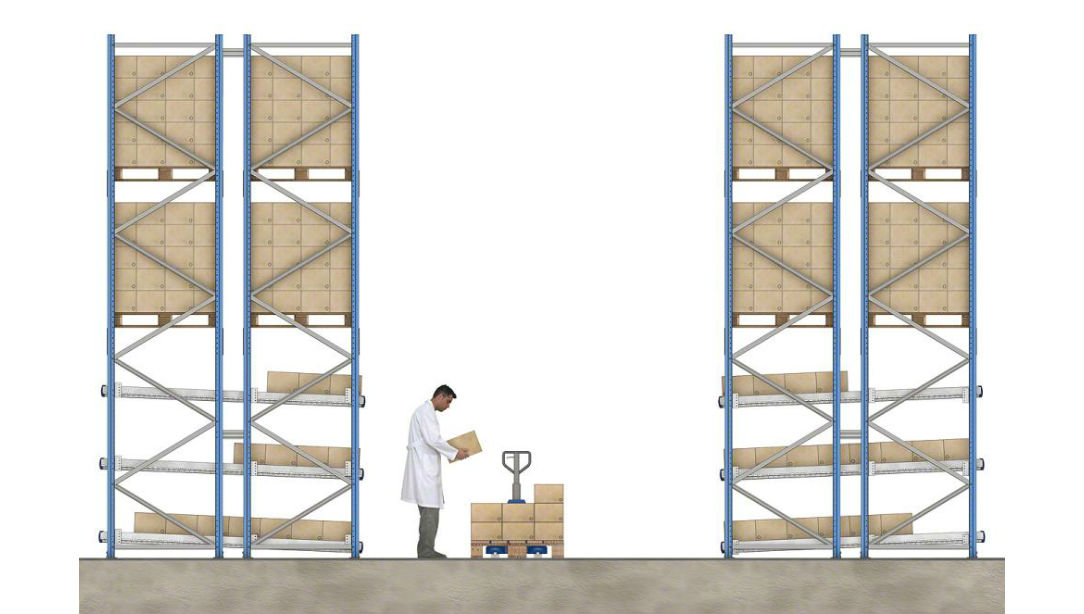

This roller type is suitable for bigger size carton with heavy load. NUTECH Heavy Duty Carton Flow Rack.

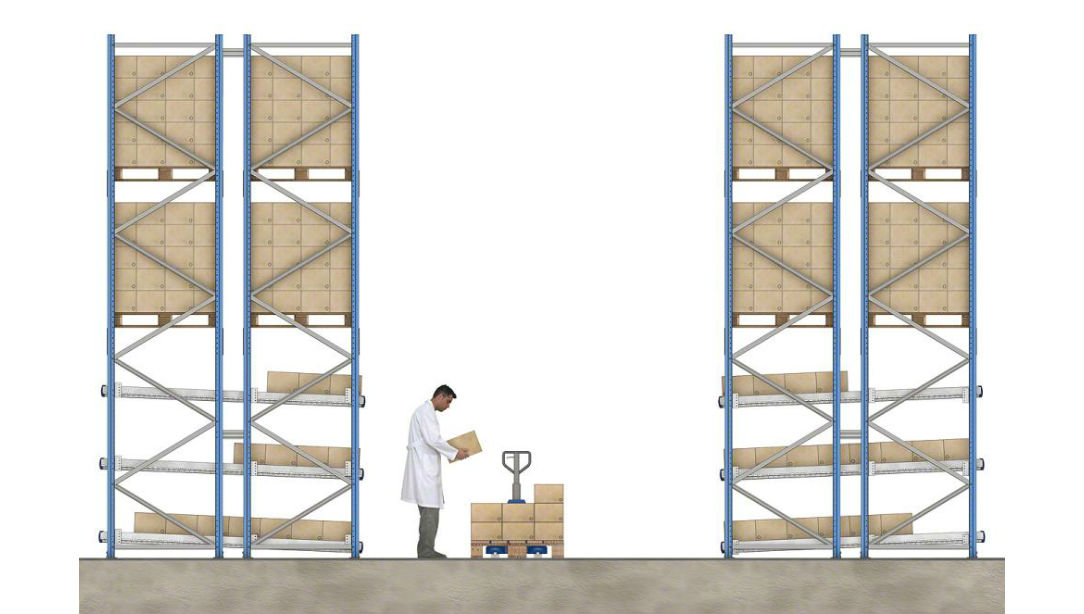

NUTECH Carton Flow Rack can be incorporated with Pallet Racking. The bottom shelf is suitable for replenishing and picking, directly retrived from the upper beam level that are used for pallet goods storage.

General Benefits

Increase storage space

Using less floor space for more storage capacityostly floor space.

Reduce labor cost

Creating a streamlined operation floor with less people for manual handling

Increase productivity

Increasing your sales with increased productivity

Ideal for FIFO

The perfect solution for industries that need to operate under First-In-First-Out method. Industries includes Perishable Food, Pharmaceutical, Dairy, FMCG, and more.

Applications

Illustration of Selective Pallet Rack System in a warehouse space

NUTECH Selective Pallet Racking installed at customer site

Illustration of Selective Pallet Rack System in a warehouse space

NUTECH Selective Pallet Racking installed at customer site

Illustration of Selective Pallet Rack System in a warehouse space

NUTECH Selective Pallet Racking installed at customer site

Illustration of Selective Pallet Rack System in a warehouse space

NUTECH Selective Pallet Racking installed at customer site

Illustration of Selective Pallet Rack System in a warehouse space

NUTECH Selective Pallet Racking installed at customer site

Illustration of Selective Pallet Rack System in a warehouse space

NUTECH Selective Pallet Racking installed at customer site

NUTECH Selective Pallet Racking installed at customer site

Illustration of Selective Pallet Rack System in a warehouse space

NUTECH Selective Pallet Racking installed at customer site

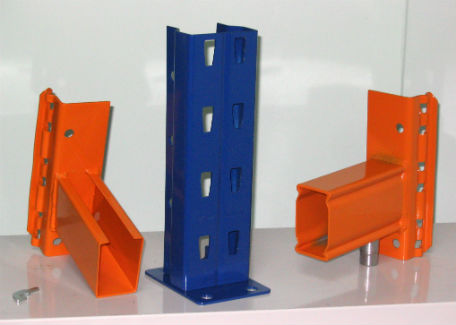

Components and Options

Frame

- 1.6mm, 1.8mm, 2.0mm thick

- N60, N90, N115

- Epoxy coated or Galvanized frame

The Details

Nutech selective pallet racking is made with the same frames as our well established pallet racking system. It is fully screwed in place and particularly well suited to heavy loads. At the top end, the frames are connected to each other with struts in side-to-side and in front-to-back direction. Additionally, the uprights of each frame are linked to each other by horizontal and diagonal struts to ensure that all parts of the frame are solidly connected to provide excellent rigidity.

.jpg)

Hook-in Beam

- Rapid assembly

- Adjustable height

- For heavy-duty applications

The Details

Rapid assembly thanks to a straightforward boltless system: The 3 or 4 hooks of the bracket perfectly slot into the upright perforations. Unintentional lifting is prevented by a safety pin which is secured against dropping out by a 90' turn. The hooked bracket is also designed to hold heavy loads and its height can be adjusted in 75mm intervals.

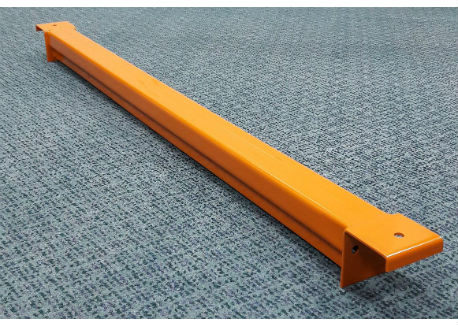

Pallet Support Bar

- Heavy duty, welded cuff design

- Easy installation, drops in place

- Epoxy powder coated

The Details

The pallet support bars provide additional safety and security under your pallet when installed in pallet racking system. Reduce load times because they give forklift driver confidence in loading pal

Frame Protector

- Protects the frame from damage

- Epoxy coated

The Details

The frame protector is placed at the further end of a row to protect the frame from damage or collision with material handling equipment.