Ideal If...

|

|

|

|

Rack Supported Platform

What is Rack Supported Platform

As a type of NUTECH Multitier System or Mezzanine Platform, Rack Supported Platform takes maximum advantage of the height of premises, doubling or tripling the surface area and enabling it to be fitted out as a storage area, changing room, or offices, etc. 2 Rack Supported Platform are being widely used in the market now and that is Long-span Supported Platform and Selective Pallet Supported Platform whereby the structure is supported by complete racking system for storage. This design enables both the ground floor and higher levels to be fully utilized for storage, effectively increasing storage capacity in the same space.

All NUTECH Multitier or Mezzanine System including Rack Supported Platform is totally dismountable and re-usable, and their structure, dimensions, and location are easily modified.

Advantages

- Multiplies surface space in industrial premises.

- Adaptable to the specific needs of the client, thanks to the great variety of sizes available, types of floors, construction systems, etc.

- Quick to assemble and easy.

- They can be complemented with a variety of accessories including wire-mesh panel, steel shelving, pallet support, and more.

HOW IT WORKS

Take full advantages of your facility height, Triple your storage capacity.

The Rack Supported Platform is a storage facility suitable for heavy duty storage. The access to additional tiers is via a structural staircase designed to provide safe and effective handling. Available with a range of beams, the systems can also be used with plywood or steel shelving.

NUTECH Rack Supported Platform is flexible and can be designed to support the open mezzanine floor or as multitier with walkways supported by rack itself. Depending on your requirements, NUTECH designs and implements our range of upright and beam profiles, rails, floor decking, stairs, and handrails.

Quality work and maximum safety on all levels are our utmost priorities. Rest assured that your loading needs on each level are covered by our design expertise.

Longspan Rack Supported Platform erected at site with Wiremesh Back Panel. Complete with plywood decking with shelf support.

Platform flooring is 18mm/25mm thick Plywood depending on customer requirement. Galvanized Perforated Steel Plank Floor Deck is available as an option to customer.

Pallet Jack is suitable to be used on our flooring. NUTECH Swing-type Pallet Gate allow for fast and efficient loading and unloading of palletized goods.

Platform supported by NUTECH floor beams and floor joists with 400mm or 600mm pitch to suit customer specific requirement. Double-Cup Upright is pictured here.

Longspan Rack Supported Platform erected at Jakarta, Indonesia.

Platform flooring is Galvanized Perforated Platform. Safe, Hygienic, Wheel Friendly.

Staircase is positioned for easy access to the first tier and second tier. Perforated Steel Planks secured on Floor Joists ensures a safe and sturdy walkway on NUTECH platform.

Handrails on first tier and second tier to prevent workers from falling over the edge. Pallet Gate is pictured on the left. Galvanized as flooring material, and Plywood as shelves decking material.

General Benefits

High Storage Density

Designed specifically to suit your manual handling and requirement on site, this racking system offer optimized vertical storage.

Cost Effective

Multitier Long-span System saves the cost of additional investment for space, making it one of the most cost effective solution to increase storage capacity in a limited space .

More Storage Capacity

Make use of your vertical space for more storage capacity!

Flexible Configuration

Multitier Long-span System is adaptable to expansion and adjustment vertically and horizontally.

Components and Options

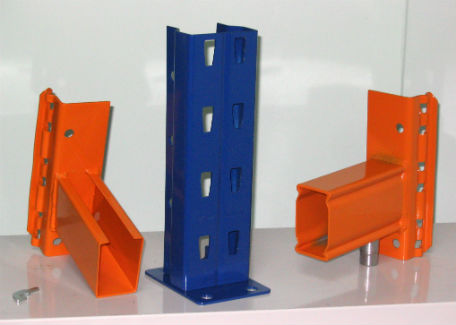

Frame

- 1.6mm, 1.8mm, 2.0mm thick

- N60, N90, N115

- Epoxy coated or Galvanized frame

The Details

Nutech selective pallet racking is made with the same frames as our well established pallet racking system. It is fully screwed in place and particularly well suited to heavy loads. At the top end, the frames are connected to each other with struts in side-to-side and in front-to-back direction. Additionally, the uprights of each frame are linked to each other by horizontal and diagonal struts to ensure that all parts of the frame are solidly connected to provide excellent rigidity.

.jpg)

Hook-in Beam

- Rapid assembly

- Adjustable height

- For heavy-duty applications

The Details

Rapid assembly thanks to a straightforward boltless system: The 3 or 4 hooks of the bracket perfectly slot into the upright perforations. Unintentional lifting is prevented by a safety pin which is secured against dropping out by a 90' turn. The hooked bracket is also designed to hold heavy loads and its height can be adjusted in 75mm intervals.

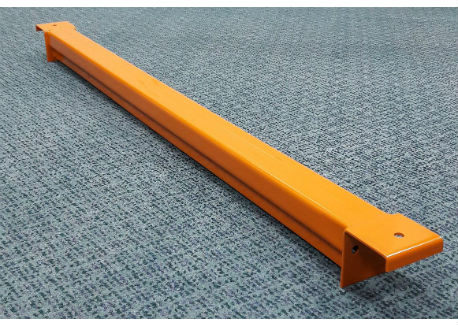

Pallet Support Bar

- Heavy duty, welded cuff design

- Easy installation, drops in place

- Epoxy powder coated

The Details

The pallet support bars provide additional safety and security under your pallet when installed in pallet racking system. Reduce load times because they give forklift driver confidence in loading pal

Frame Protector

- Protects the frame from damage

- Epoxy coated

The Details

The frame protector is placed at the further end of a row to protect the frame from damage or collision with material handling equipment.